Contents†

多段液体分離†

Figure 1

Schematic illustration of the multi-step liquid phase separation [1,5].

Figure 2

Various-size Cu-globules dispersed Fe-based metallic glass. The unique fractal structure was formed through the multi-step liquid phase separation [4,5].

Recently, two-phase amorphous alloys have been obtained through liquid phase separation in La-Zr-Al-Ni-Cu[1], Y-Ti-Al-Co[2], and Ni-Nb-Y[3] by means of rapid solidification. In a multi-component alloy system, phase separation in a liquid state occurs first, after which each liquid region undergoes a liquid-to-glass transition, resulting in the formation of a two-phase amorphous alloy. These alloys systems also show an unique behavior of "multi-step liquid phase separation". Figure 1 shows the schematic illustration of multi-step liquid phase separation. We try to develop new metallic materials based on the concept of multi-step liquid phase separation in Fe-Cu and Co-Cu based alloys [4,5]. Figure 2 shows the typical example of Fractal-like structure formed by multi-step liquid phase separation in Fe-Zr-B-Cu alloys [4,5].

REFERENCES

[1] A.A Kundig, M. Ohnuma, D.H. Ping, T. Ohkubo, K. Hono, Acta Mater. 52, 2441 (2004).

[2] B.J. Park, H.J. Chang, D.H. Kim, W.T. Kim: Appl. Phys. Lett. 85, 6353, (2004).

[3] N. Mattern, U. Kuhn, A. Gebert, T. Gemming, M. Zinkevich, H. Wendrock, L. Schultz: Scripta Mater. 53, 271, (2005).

[4] T. Nagase, A. Yokoyama and Y. Umakoshi: Mater. Trans, 47, 1105-1114 (2006). http://www.jim.or.jp/journal/e/47/04/1105.html

[5] T. Nagase, A. Yokoyama and Y. Umakoshi: J. of alloys and compounds, 494, 295-300 (2010). http://dx.doi.org/10.1016/j.jallcom.2010.01.015

チタン合金の液体分離†

Figure 1

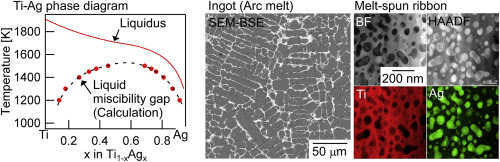

Metastable liquid miscibility gap and solidification microstructure in Ti-Ag alloys.

Ti-Ag 合金は、状態図において平滑な液相線を示すことが大きな特徴です。Ti-Ag合金は、液体超急冷によって液体分離の発現にともなう特徴的な組織をしめすともに、金属間化合物の形成が抑制されます。Ti-Ag系合金における液体分離現象の発現と特異な凝固組織の形成は、Ti-Nb-Ag合金でも見られます。

REFERENCES

- T. Nagase, Materials, 13, 5268 (2020)., "Alloy design, thermodynamics and electron microscopy of ternary Ti-Ag-Nb alloy with liquid phase separation", https://doi.org/10.3390/ma13225268

- T. Nagase, M. Matsumoto, Y. Fujii, Journal of Alloys and Compounds, 738, 440-447 (2018)., "Microstructure of Ti-Ag immiscible alloys with metastable liquid phase separation", https://doi.org/10.1016/j.jallcom.2017.12.1388

- T. Nagase, M. Matsumoto, Y. Fujii, Microscopy, 66 S1, i22 (2017)., "Microstructure of Ti-Nb-Ag immiscible alloys with liquid phase separation", https://doi.org/10.1093/jmicro/dfx064

REFERENCES (Review)

- 永瀬丈嗣, 松本恵, 藤居義和, 日本学術振興会172委員会 研究報告書, Vol. 18, No. 1, 61-74 (2018)., "チタン合金の液体分離", https://www.jsps.go.jp/j-soc/list/172.html

ハイエントロピー合金の液体分離†

REFERENCES

- T. Nagase, T. Tamura, Materials Transactions, 64, 1645-1654 (2023)., "Solidification Microstructures in 3d-Transition Metal High Entropy Alloys with Cu Element", https://doi.org/10.2320/matertrans.MT-D2023002

- T. Nagase, M. Todai, T. Nakano, Crystals, 10, 527, (2020)., "Liquid Phase Separation in Ag-Co-Cr-Fe-Mn-Ni, Co-Cr-Cu-Fe-Mn-Ni and Co-Cr-Cu-Fe-Mn-Ni-B High Entropy Alloys for Biomedical Application", https://doi.org/10.3390/cryst10060527

- T. Nagase, M. Todai, T. Nakano, Scripta Materialia, 186, 242-246 (2020)., "Development of Ti–Zr–Hf–Y–La high-entropy alloys with dual hexagonal-close-packed structure", https://doi.org/10.1016/j.scriptamat.2020.05.033

- T. Nagase, M. Todai, T. Nakano, Materials Transactions, 61, 567-576 (2020)., "Development of Co-Cr-Mo-Fe-Mn-W and Co-Cr-Mo-Fe-Mn-W-Ag High-Entropy Alloys Based on Co-Cr-Mo alloys", https://doi.org/10.2320/matertrans.MT-MK2019002

- T. Nagase, Material Science Forum, 941, 1366-1371 (2018)., "Microstructure of Co-Cr-Fe-Mn-Ni-Ag and Co-Cr-Fe-Mn-Ni-Cu High Entropy Alloys with Liquid Phase Separation", https://doi.org/10.4028/www.scientific.net/MSF.941.1238

マクロ相分離リボン†

Figure 1

Macroscopically phase separated melt-spun ribbon. Continuous rapidly solidified ribbon shows Co-Si-B amorphous / Cu crystal dual layer structure [1,2]

We firstly develop a dual-layer ribbon by conventional single-roller melt-spinning method [1,2]. In Co-Cu-Si-B melt-spun ribbon, the roll-side surface comprised Co-Si-B-based amorphous phase with Cu crystalline nanoscale globules, while the free surface showed a thin crystalline Cu layer. A macroscopically separated unique structure was obtained by the simultaneous occurrence of liquid phase separation of the Co-Cu-based alloy system and amorphous phase formation in the Co-Si-B alloy layer.

REFERENCES

[1] T. Nagase and Y. Umakoshi: J. of alloys and compounds, 505, L43-L46 (2010)., http://dx.doi.org/10.1016/j.jallcom.2010.06.092

[2] T. Nagase and Y. Umakoshi: Intermetallics 18, 2136-2144 (2010)., http://dx.doi.org/10.1016/j.intermet.2010.06.020

マクロ相分離ワイヤー†

Figure 1

Macroscopically phase separated melt-extracted wire. Continuous rapidly solidified wire shows Fe-Si-B amorphous core/Cu crystal cover layer structure [1].

We firstly develop a rapidly solidified Fe-Cu-Si-B alloy with a macroscopically separated structure by the arc-melt-type melt-extraction method [1]. A unique core-wire/surface-cover-layer structure composed of core Fe-Si-B-based amorphous alloy and cover Cu crystal was formed by liquid phase separation during rapid quenching of thermal melt.

REFERENCES

[1] T. Nagase and Y. Umakoshi: J. of alloys and compounds, 495, L1-L4 (2010)., http://dx.doi.org/10.1016/j.jallcom.2010.01.127

液体分離 : 合金系による分類†

Fe-Cu

- T. Nagase, A. Yokoyama and Y. Umakoshi, J. of alloys and compounds, 509, 1178-1186 (2011)., "Formation of Macroscopically Phase Separated Cu-colored Melt-spun Ribbon in (Fe0.5Cu0.5)100-xBx (x = 0, 5, 10, and 20) Alloys", http://dx.doi.org/10.1016/j.jallcom.2010.09.168

Fe-Cu-B

- T. Nagase, A. Yokoyama and Y. Umakoshi, J. of alloys and compounds, 509, 1178-1186 (2011)., "Formation of Macroscopically Phase Separated Cu-colored Melt-spun Ribbon in (Fe0.5Cu0.5)100-xBx (x = 0, 5, 10, and 20) Alloys", http://dx.doi.org/10.1016/j.jallcom.2010.09.168

Fe-Cu-Si-B

- T. Nagase, M. Suzuki, T. Tanaka, Intermetallics, 61, 56-65 (2015)., "Formation of amorphous phase with crystalline globules in Fe-Cu-Si-B and Fe-Cu-Zr-B immiscible alloys", http://dx.doi.org/10.1016/j.intermet.2015.02.006

- 永瀬丈嗣, 鈴木賢紀, 田中敏宏, 材料, 64. 175-182 (2015)., "液相分離を示すFe-M-Si-B (M=Cu, Ag, Sn)急速凝固合金の組織", (T. Nagase, M. Suzuki, T. Tanaka, J. of the Society of Materials Science, 64. 175-182 (2015)., "Microstructure of rapidly solidified Fe-M-Si-B (M=Cu, Ag, Sn) immiscible alloys"), http://dx.doi.org/10.2472/jsms.64.175

- T. Nagase, Y. Umakoshi, J. of alloys and compounds, 495, L1-L4 (2010)., "Formation of melt-extracted wire of Fe-Cu-Si-B alloy with core-wire/surface-cover-layer structure by arc-melt-type melt-extraction method", http://dx.doi.org/10.1016/j.jallcom.2010.01.127

Fe-Cu-Nb-B

- T. Nagase, M. Suzuki, T. Tanaka, Journal of alloys and compounds, 619, 267-274 (2015)., "Formation of amorphous phase with crystalline globules in Fe-Cu-Nb-B immiscible alloys", http://dx.doi.org/10.1016/j.jallcom.2014.08.229

Fe-Cu-Zr-B

- T. Nagase, Y. Umakoshi, Surface and Interface Analysis, 48, 1252-1255 (2016)., "Microstructure of nano-crystalline globules embedded in an amorphous matrix in immiscible alloys", http://dx.doi.org/10.1002/sia.6090

- T. Nagase, M. Suzuki, T. Tanaka, Journal of alloys and compounds, 619, 332-337 (2015)., "Formation of nanoglobules with core-shell structure by liquid phase separation in Fe-Cu-Zr-B immiscible alloy", http://dx.doi.org/10.1016/j.jallcom.2014.08.138

- T. Nagase, M. Suzuki, T. Tanaka, Intermetallics, 61, 56-65 (2015)., "Formation of amorphous phase with crystalline globules in Fe-Cu-Si-B and Fe-Cu-Zr-B immiscible alloys", http://dx.doi.org/10.1016/j.intermet.2015.02.006

- T. Nagase, Materials Transactions, 55, 304-310 (2014)., Sharing publication - JIM(Japan Institute of Metals) and JFS(Japan Foundry Engineering Society), "Entangled Duplex Structure and Polycrystalline Globule Formation through Multistep Liquid-Phase Separation in Cu-Fe-Zr-B Alloys", http://dx.doi.org/10.2320/matertrans.F-M2013837l

- T. Nagase, A. Yokoyama and Y. Umakoshi, J. of alloys and compounds, 494, 295-300 (2010)., "Multi-Scale Crystalline Cu Globule Dispersed Fe-Based Metallic Glass Formation by Multi-Step Liquid Phase Separation", http://dx.doi.org/10.1016/j.jallcom.2010.01.015

- T. Nagase, A. Yokoyama, Y. Umakoshi, Mater. Trans, 47, 1105-1114 (2006)., "Formation of Nanocrystalline Globules and Metallic Glass in Fe70-xCuxZr10B20 (x=0~70) Alloys", http://dx.doi.org/10.2320/matertrans.47.1105

Fe-Cu-P-C

- T. Nagase, T. Terai, M. Matsumuro, M. Takemura, ISIJ International, 60, 2615-2624 (2020)., "Development of Fe-P-C-Cu Immiscible Amorphous Alloys with Liquid Phase Separation", https://doi.org/10.2355/isijinternational.ISIJINT-2020-211

Fe-Ag-Si-B

- T. Nagase, M. Suzuki, T. Tanaka, Journal of alloys and compounds, 619, 311-318 (2015)., "Amorphous phase formation in Fe-Ag based immiscible alloys", http://dx.doi.org/10.1016/j.jallcom.2014.08.212

- 永瀬丈嗣, 鈴木賢紀, 田中敏宏, 材料, 64. 175-182 (2015)., "液相分離を示すFe-M-Si-B (M=Cu, Ag, Sn)急速凝固合金の組織", (T. Nagase, M. Suzuki, T. Tanaka, J. of the Society of Materials Science, 64. 175-182 (2015)., "Microstructure of rapidly solidified Fe-M-Si-B (M=Cu, Ag, Sn) immiscible alloys"), http://dx.doi.org/10.2472/jsms.64.175

- T. Nagase, Y. Umakoshi, Intermetallics 18, 2136-2144 (2010)., "Formation of dual-layer melt-spun ribbon through liquid phase separation", http://dx.doi.org/10.1016/j.intermet.2010.06.020

Fe-Ag-P-C

- T. Nagase, T. Terai, M. Matsumuro, M. Takemura, Materials Transactions, 64, 1982-1990 (2023)., "Alloy Design and Solidification Microstructure Analysis in Fe-P-C-Ag Immiscible Metallic Glasses", https://doi.org/10.2320/matertrans.MT-Y2023001

- 永瀬丈嗣, 寺井智之, 松室光昭, 武村守, 粉体および粉末冶金, 69, 185-194 (2022)., "Fe-P-C-Ag液体分離金属ガラスの合金設計と凝固組織", https://doi.org/10.2497/jjspm.69.185

Fe-Sn-Si-B

- 永瀬丈嗣, 鈴木賢紀, 田中敏宏, 材料, 64. 175-182 (2015)., "液相分離を示すFe-M-Si-B (M=Cu, Ag, Sn)急速凝固合金の組織", (T. Nagase, M. Suzuki, T. Tanaka, J. of the Society of Materials Science, 64. 175-182 (2015)., "Microstructure of rapidly solidified Fe-M-Si-B (M=Cu, Ag, Sn) immiscible alloys"), http://dx.doi.org/10.2472/jsms.64.175

Cu-Ag-La-Fe

- T. Nagase, T. Terai, T. Kakeshita, K. Morita, Materials Transactions, 61, 311-317 (2020)., "Solidification Microstructure and Magnetic Properties of Ag-rich Ag-Cu-La-Fe Immiscible Alloys", https://doi.org/10.2320/matertrans.Z-M2019857

- T. Nagase, T. Terai, T. Kakeshita, M. Matsumoto, Y. Fujii, Materials Transactions, accepted, "Microstructure and Magnetic Properties of Cu-Ag-La-Fe Immiscible Alloys with an Amorphous Phase", https://doi.org/10.2320/matertrans.Y-M2019803

- 永瀬丈嗣, 寺井智之, 掛下知行, 森田健太, 材料, 68, 205-211 (2019)., "Ag-rich Ag-Cu-La-Fe液体分離合金の組織と磁気的性質", https://doi.org/10.2472/jsms.68.205

- 永瀬丈嗣, 寺井智之, 掛下知行, 松本恵, 藤居義和, 粉体および粉末冶金, 65, 45-51 (2018)., "Cu-Ag-La-Fe液相分離型アモルファス合金の組織と磁気的性質", https://doi.org/10.2497/jjspm.65.45

Co-Cu-Si-B

- T. Nagase, Y. Umakoshi, Journal of alloys and compounds, 650, 342-350 (2015)., "Microstructure of rapidly solidified Co-Cu-Si-B immiscible alloys with an amorphous phase", http://dx.doi.org/10.1016/j.jallcom.2015.07.230

- T. Nagase, Materials Transactions, 57, 156-162 (2016)., Sharing publication - JIM(Japan Institute of Metals and Materials) and JFS(Japan Foundry Engineering Society), "Formation of various type of globules in Co-Cu-Si-B immiscible alloy with an amorphous phase",http://dx.doi.org/10.2320/matertrans.F-M2015835

- T. Nagase, Y. Umakoshi, Intermetallics 18, 2136-2144 (2010)., "Formation of dual-layer melt-spun ribbon through liquid phase separation", http://dx.doi.org/10.1016/j.intermet.2010.06.020

- T. Nagase, Y. Umakoshi, J. of alloys and compounds, 505, L43-L46 (2010)., "Formation of macroscopic phase-separated dual-layer melt-spun ribbon from Co-Si-B-Cu alloy", http://dx.doi.org/10.1016/j.jallcom.2010.06.092

Co-Cu-Zr-B

- T. Nagase, Y. Umakoshi, Journal of alloys and compounds, 649, 1174-1181 (2015)., "Amorphous phase formation in Co-Cu-Zr-B based immiscible alloys", http://dx.doi.org/10.1016/j.jallcom.2015.07.229

Co-Cu-Zr-Ti-B

- 永瀬丈嗣, 馬越佑吉, 粉体および粉末冶金, 63, 217-222 (2016)., "Co-Cu-Zr-Ti-B合金系におけるアモルファス相形成", (T. Nagase, Y. Umakoshi, J. of the Japan Society of Powder Metallurgy, 63. 217-222 (2016)., "An Amorphous Phase Formation in Co-Cu-Zr-Ti-B Alloy System"), http://doi.org/10.2497/jjspm.63.217

Al-Bi

- T. Nagase, Materials Transactions, 64, 1655-1662 (2023)., "Design and Characterization of Al-Co-La-Bi Multicomponent Immiscible Alloys with Liquid Phase Separation and an Amorphous Phase Formation", https://doi.org/10.2320/matertrans.MT-M2023011

Al-Pb

- T. Nagase, M. Takemura, M. Matsumuro, M. Matsumoto, Y. Fujii, Materials and Design, 117, 338-345 (2017)., "Microstructure of globules embedded in an amorphous phase in Al-Co-La-Pb immiscible alloys", http://dx.doi.org/10.1016/j.matdes.2016.12.092

Ti-Ag

- T. Nagase, M. Matsumoto, Y. Fujii, Journal of Alloys and Compounds, 738, 440-447 (2018)., "Microstructure of Ti-Ag immiscible alloys with metastable liquid phase separation", https://doi.org/10.1016/j.jallcom.2017.12.138

Ti-Ag-Nb

- T. Nagase, Materials, 13, 5268 (2020)., "Alloy design, thermodynamics and electron microscopy of ternary Ti-Ag-Nb alloy with liquid phase separation", https://doi.org/10.3390/ma13225268

- T. Nagase, M. Matsumoto, Y. Fujii, Microscopy, 66 S1, i22 (2017)., "Microstructure of Ti-Nb-Ag immiscible alloys with liquid phase separation", https://doi.org/10.1093/jmicro/dfx064

|

![[PukiWiki] [PukiWiki]](image/01.png) Top/液体分離合金

Top/液体分離合金

![[PukiWiki] [PukiWiki]](image/01.png) Top/液体分離合金

Top/液体分離合金